Rigid PVC sheet core formula components

Rigid PVC sheet core formula components

The design of rigid PVC formula involves the reasonable combination and blending of multiple components, and the selection of these components directly affects the performance of rigid PVC materials. The following are several key components commonly found in rigid PVC formulas:

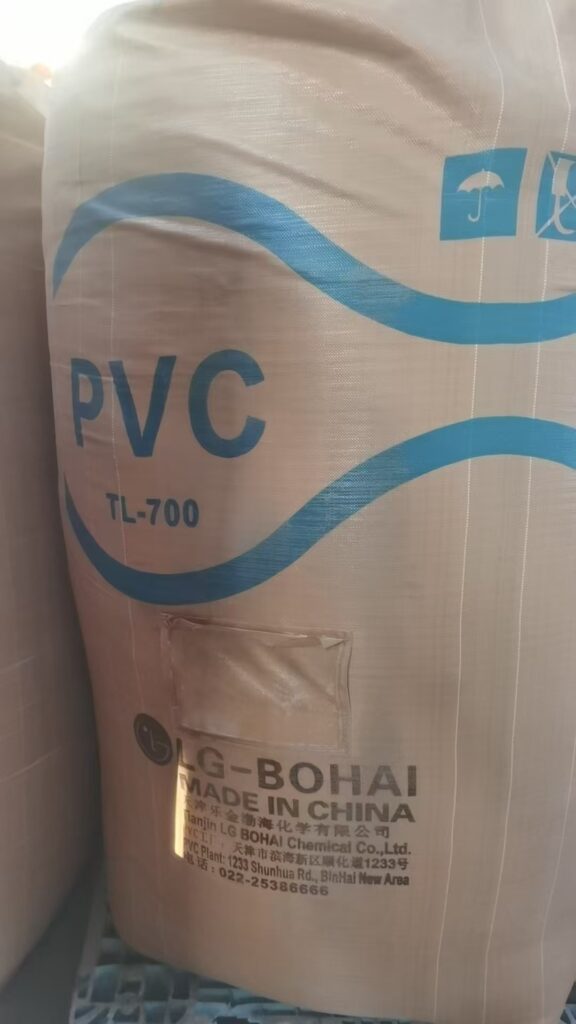

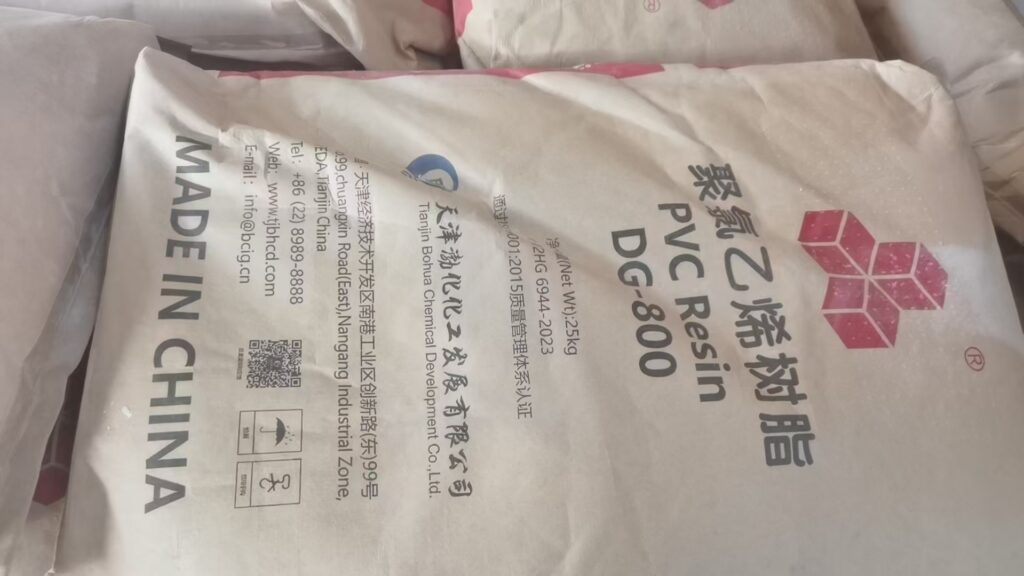

– Polyvinyl chloride resin (PVC resin)

As the main component of rigid PVC, PVC resin determines its basic physical properties. PVC resin generally has good processing performance and high mechanical strength, serving as the foundation in rigid PVC formulas.

– Stabilizers

Stabilizers are essential auxiliary agents in the processing of PVC resin, mainly used to prevent thermal degradation of PVC at high temperatures. Common stabilizers include calcium-zinc stabilizers, lead salt stabilizers, and organic tin stabilizers. Among them, calcium-zinc stabilizers have become the most widely used due to their environmental friendliness.

– Plasticizers

Plasticizers are mainly used to adjust the processability and flexibility of PVC. Although the main characteristic of rigid PVC is high rigidity, slight plasticizing effects can help improve processability in some applications.

– Fillers

The addition of fillers is mainly to reduce costs and improve the physical properties of rigid PVC. Common fillers include calcium carbonate, talcum powder, etc., which can enhance the weather resistance, impact resistance, and wear resistance of rigid PVC.

– Additives and modifiers

Additives and modifiers are used to further optimize the characteristics of rigid PVC, such as improving its UV resistance and anti-aging performance. For special applications, functional additives such as antibacterial agents and flame retardants may also be added.