Rigid PVC sheet production process &application

Rigid PVC sheet production process mainly include two methods: extrusion and calendering. Its main applications blister packaging, chemical, electronics and other fields.

Production Processes

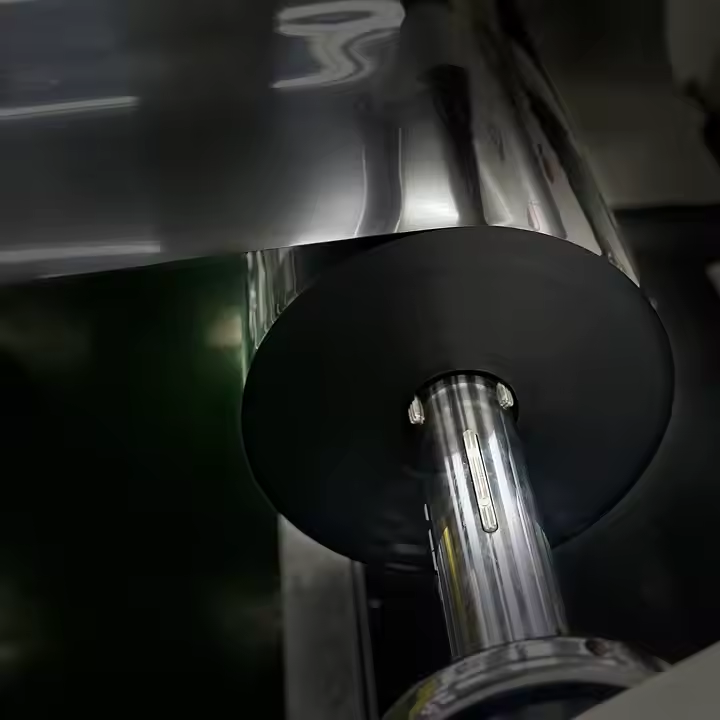

1. Extrusion Molding

After uniformly mixing PVC resin with various additives, the mixture is heated and melted by an extruder, then extruded into sheets. This method allows precise control of sheet thickness and is suitable for mass production.

2. Calendering Molding

After uniformly mixing PVC resin with additives, the mixture is heated and calendered by a calender to form sheets. Sheets produced by this method have a smooth surface and uniform thickness, making them suitable for products with high surface quality requirements.

Main Applications

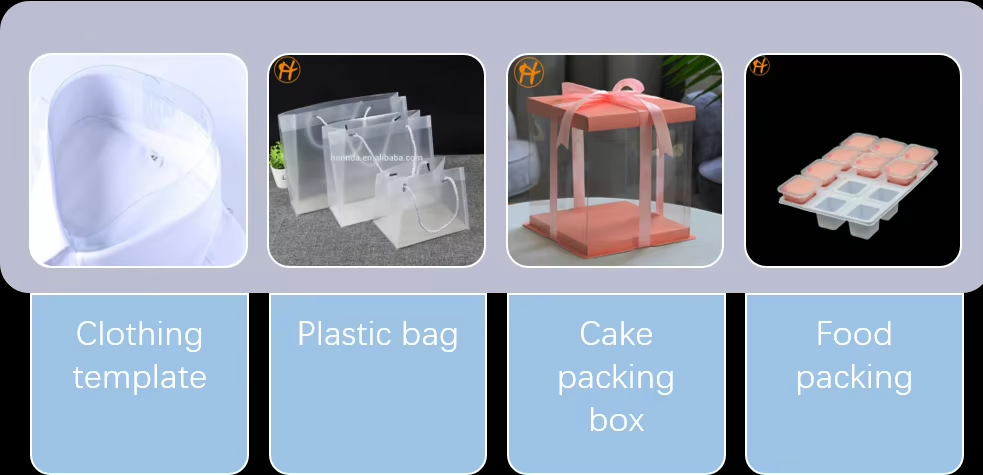

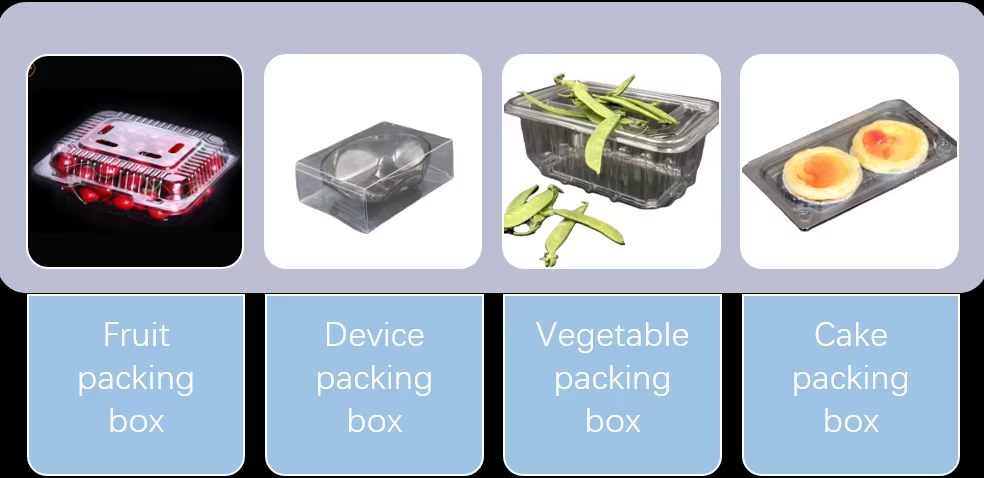

– Packaging

Rigid PVC sheets are used to make various packaging boxes, blister packs, etc. With good transparency and moisture resistance, they effectively protect products.

– Chemical Industry

Rigid PVC sheets are used to make corrosion-resistant containers, pipelines, etc., and are widely applied in the chemical industry.

– Electronics

Rigid PVC sheets are used to make casings and insulating materials for electronic products, featuring excellent insulation and mechanical strength.

– Others

Rigid PVC sheets can also be used to make signs, billboards, stationery, etc.

Summary

Rigid PVC sheets play an important role in various industries due to their excellent properties and wide applications. With the continuous development of technology, the application fields of rigid PVC sheets will continue to expand.